CNC

Why Choose Us

Rich Experience

After more than ten years of industry experience and technology accumulation, Xinrui Company has developed into a one-stop medical parts and finished products full ecological chain service manufacturer integrating industrial design, mold design, solid silica gel/liquid silica gel, finished product assembly, etc.

Quality and Price

Our products are of high quality and competitive price.

Production Capacity

Advanced production equipment and rich operating experience.

Customized Service

We provide customized products that can meet the strict requirements of customers.

What is CNC

Computer Numerical Control, commonly written as CNC, is a type of control system that can provide automated movement and working of the machine tool. The instructions in CNC technology are written in a code format. The code is then uploaded to the machine with internal computers to analyze and interpret it.It is common for CNC technology to be used in conjunction with subtractive CNC machining processes such as drilling rigs, milling machines, lathes, turning, and routers. It can also work in combination with additive technology like 3D printing.

Benefits of CNC

Results in Greater Accuracy

CNC machinery operates autonomously with little to no manual intervention, eliminating human errors in the manufacturing process. Advanced software and coding governs the machining process, delivering greater accuracy than is capable with human hands and actions. Plus, CNC machining relies on immutable digital inputs throughout each cycle in a continuous process for as long as necessary, meaning there are no compromises on quality. CNC machines do not get tired.

Results in Faster and More Efficient Production

CNC machining not only results in greater accuracy but its speed is unmatched by human efforts. These complex machines can run at high speed 24 hours a day if necessary, without tiring, breaks, or pauses for recalibration. Fast, accurate machining of parts means highly efficient production rates, which also contributes to quicker assembly processes. Even manual assembly lines are made more efficient by using CNC machining to produce parts that fit seamlessly together.

Produces Little Waste

CNC machinery software includes built-in coding that intuitively optimizes how a component is machined to reduce waste. Test models are run in simulation to determine optimal methods, so the final CAD-CAM model will produce exemplary results with near-zero wasted material from the first cycle. Moreover, CNC machining uses repeatable software, fixed tools, and fixed material routing to make the most efficient use of raw materials.

Enhances Personnel Safety

A significant benefit of CNC machining is how the complex production at high speed is completely isolated from human operators, enhancing their safety. Modern computer programming handles every adjustment, tool change, adding and removing raw material and finished products, and more without any necessary contact with a person. Operator involvement is limited to supervisory roles with remote monitoring and required maintenance during downtime.

Reduces Production Costs

Every energy-intensive manufacturing industry seeks ways to reduce energy consumption to reduce costs, gas emissions, and other environmental hazards. CNC machining is already an energy-efficient and labor-saving method of manufacturing that saves precious resources. Only the exact amount of effort is expended to complete precision milling operations, reducing energy use, raw materials, and other production costs. Plus, increased safety and efficiency reduces operational costs and financial liabilities from accidents and injuries.

Motion type CNC

Motion type CNC control system units are further divided into two main types, which are:

●Contouring systems:These machine tools are known to work in a continuous path where they focus on cutting the material presented to them and following its contour as such. Their basic functioning is inclusive of processes like luke milling, lathe, and routing machines.These contouring machines function through the simulatory movement of the tool and work positions. Both the position f the machine as well as the product are controlled by the control system.

●Point to point control systems:In this case, both the workpiece and the tool are kept in a constant position while the tool performs its required duty. The major members of such machines which function through point-to-point mechanisms include drilling machines, tapping machines, boring machines, and more.

Loop control CNC systems

This part of the classification further branches into two depending upon the looping system involved in the procedure.Closed-loop systems This type of CNC control system works through a process that has feedback from the control system sent to the actual and programmed input. This is why it is referred to as a closed-loop system.In this case of a CNC control system working under the servo mechanism, the feedback can be possibly measured through either analog or digital systems. With such closed-loop systems, you achieve high levels of power and accuracy thanks to their extensive capability and monitoring.Open-loop systems.Here, the instructions are sent into the control via the input device, which is then converted to the signals by the controller. These converted signals are then sent to the servo amplifiers to energize the motors.

Number of axis type CNC control systems

This is a rather extensive segment of the CNC control system classification and is inclusive of 5 sub-classes of highly competent machine systems. The only thing varying in these devices is the number of axes which is clear from the name itself. However, this difference is all it takes to create notable changes in how it can complement your business specifically.

Application of CNC

Woodworking Industries

Wooden furniture is often CNC machined to save time and reduce cost. Manually carving wooden parts is extremely time-consuming and costly. CNC machines can be used to create furniture with complex geometries that would have otherwise required a master woodworker to achieve.

Lettering and Engraving Systems

Some applications don't require the heavy-duty removal of material, but rather make use of an engraving tool to mark patterns or text onto the surface of a part. This application can be done for artistic applications or serialized parts.

Electrical Industry

Demand for CNC-machined parts for the electronics industry covers a wide spectrum of applications. Machining component mounting holes into printed circuit boards and machining aluminum or copper heat sink for heat-generating electrical components are some examples of the use of CNC machining in the electronics industry. Get started on a new Small Batch CNC Machining Quote.

Pharmaceutical Industry

CNC machines are used to manufacture precise equipment for use in the production of pharmaceutical products. Applications can include extremely precise metering pumps, ingredient-dispensing nozzles, and packaging. Get started on a new Production CNC Machining Quote.

Food and Beverage Industry

The fast-moving consumer goods industry makes use of a wide range of custom material-handling machinery that makes use of CNC machined parts. Food packaging is also made from injection molded plastics whose molds are CNC machined.

Components of CNC

Microcontroller

Microcontroller is the brain of a CNC system. It interprets the language of the programs and provides instructions to the corresponding machine parts based on the commands. It is also known as Machine Control Unit (MCU) or CNC controller.

Input Device

The input device enables the operator to load various programs in the CNC machine. Certain settings may be adjusted through the input devices. Standard input devices are keyboard and mouse.

Output Device

The output device provides the operator details about the machine status and other important information, such as errors. Common output devices are the display monitor and alarms.

Software Programs

CNC systems require a software program to write the instructions that the machine can understand. There are many different types of CNC software. Most commonly used CNC software programs are CAD software and CAM software.

How to Choose CNC

Machining Requirements

Start by identifying your specific machining requirements. Determine the type of parts you need to produce, their size, complexity, and the materials you'll be working with. Consider the required precision, surface finish, and any special features or operations you need to perform.

CNC System Compatibility

Ensure that the CNC system you choose is compatible with the lathe machine you intend to use or vice versa. Check if the machine manufacturer recommends specific CNC systems or if they offer integrated solutions. Consider factors such as programming language, control capabilities, and available options for customization.

Machine Size and Capacity

Assess the size and capacity of the lathe machine based on your workpiece sizes and production volume. Consider factors such as swing diameter, maximum turning length, chuck size, and spindle power. Ensure that the machine can handle your workpiece dimensions and weight requirements.

Automation and Integration

Determine the level of automation and integration you require. Consider if you need features like automatic tool changers, robotic loading/unloading, or part inspection capabilities. Evaluate the compatibility and availability of automation options for both the CNC system and the lathe machine.

Precision and Accuracy

Consider the required precision and accuracy for your machining tasks. Look for lathe machines with features like high-resolution encoders, rigid construction, and precision ball screws. Ensure that the CNC system offers precise control over positioning and feed rates, and supports high-precision machining operations.

Software and Programming

Evaluate the software and programming capabilities of the CNC system. Consider factors such as ease of use, programming language, availability of CAM software integration, simulation capabilities, and compatibility with your existing software ecosystem. Ensure that the system provides the necessary programming tools and flexibility for your machining needs.

Process of CNC

Designing the CAD Model

A CAD (Computer Aided Design) 3D model is developed by an engineer or designer. This part is designed according to specific CNC design principles, which are included in the overall DFM (Design for Manufacturing) philosophy. DFM ensures that the part can be efficiently manufactured on a CNC machine. For CNC parts, it is not strictly necessary to create 2D drawings of the part, since the machine instructions are created using CAM software which generates machine instructions. However, 2D drawings are often generated to indicate key dimensions for quality control purposes.

Converting the CAD File to a CNC Program

The CAD file is exported to a CAM (Computer Aided Manufacturing) software package that contains a range of tools to convert the 3D model into a set of instructions that can be understood by the CNC machine. CAM software is normally used by CNC machine operators to generate G-code. At the end of the process, a G-code file is saved to the machine. This file contains all the relevant instructions required to manufacture the part.

Preparing the CNC Machine

Preparing the machine to fabricate a new part number starts with setting up the required fixturing to hold the raw stock material in place while the cutting tool removes material. Alternatively, the raw stock is fixed in a spindle and stationary cutting tools are presented to the rotating stock piece to remove material. The required tooling must be checked for wear or chips and placed into the machine. More advanced CNC machines have automatic tool changers and tool libraries that allow the machine to automatically select the relevant tool needed to machine a specific feature without having to wait for the operator to swap out tools.

Executing the Machining Operation

When the material is securely clamped into the machine, the correct tooling is selected and the G-code is loaded, the actual machining can commence. Once the cycle-start button is pressed the machine will select the appropriate tool, move to the workpiece and begin removing material as per the G-code instructions and will continue until the part is complete. For operations that require machining with more than one type of tool, or with the part in more than one orientation, some CNC machines may require the operator to reposition the in-process work material between operations.

How to Maintain CNC

Daily Maintenance

Cleanliness is Crucial Maintaining a clean CNC machine is paramount. Dust, chips, and debris can lead to performance issues and wear on critical components.Start each day by blowing away chips and dust with compressed air.Wipe down surfaces with a clean, lint-free cloth.Ensure that coolant and lubrication systems are clean and free from contamination.Inspect Toolholders and Workholding Devices Check toolholders, collets, and workholding devices daily for signs of damage or wear. Replace any components that appear compromised to maintain precise tool alignment.

Weekly Maintenance

Examine Way Covers and Bellows Way covers and bellows protect critical machine components from contaminants. Inspect them weekly for damage or leaks and replace any compromised parts to prevent issues.Spindle and Taper Maintenance Clean the spindle and taper thoroughly, removing debris or buildup. Inspect for wear and have them professionally serviced or replaced if necessary.Check Electrical Connections Regularly inspect all electrical connections, wires, cables, and connectors for wear or loose connections. Reliable electrical connections are crucial for CNC machine performance and safety.

Monthly Maintenance

Vibration Assessment Look for any unusual vibrations or noises. Vibration can indicate issues with bearings, belts, or other moving parts. Address problems promptly to prevent further damage.Tool Change Mechanism Ensure that the automatic tool change mechanism operates smoothly. Clean and lubricate it as per the manufacturer's recommendations to ensure it functions correctly.Axis Alignment Verification Confirm the alignment of the machine's axes by performing a precision calibration check. Correct any misalignment promptly to maintain the machine's accuracy.

Quarterly Maintenance

Ball Screws and Linear Guides Inspection Inspect ball screws and linear guides for signs of wear, damage, or contamination. Clean and lubricate them according to the manufacturer's guidelines. Replace worn components to prevent costly repairs later on.Coolant System Check Perform a thorough inspection of the coolant system, including pumps, filters, and hoses. Replace any worn or damaged parts and clean filters to ensure efficient cooling and chip evacuation.Controller and Software Updates Check for available controller or software updates provided by the manufacturer. Keeping your CNC machine's software up to date can enhance performance and security.

Future of CNC Technology

Virtual Reality

Virtual Reality in CNC systems is highly useful for operator training. Operators can now learn about the machine and its features in a virtual environment identical to the real world system. This provides complete learning to the operator without any risks of accidents involved with operation of the machine. Additionally, operators can test the various complex features of modern machines without the risk of machine malfunction.

Robotics

Integrating robotics with CNC creates advanced machinery that pushes the limits of what is possible. Manufacturing industries can now create parts in a completely automated manner from end to end. Even the loading and unloading of parts can be done with robotic arms. The integration of robotics also maximizes the machine precision and production rate.

Artificial Intelligence

The primary direction of growth is the addition of Artificial Intelligence to the CNC technology. CNC machines can learn from the operations and provide efficient feedback to optimize manufacturing methods and remove any bottlenecks. Additionally, multiple CNC systems can be incorporated on a single manufacturing line and controlled remotely by the operator through digital means.

Our Factory

Xinrui Company was established in 2005, focusing on the R&D, designing, processing and production of components for medical equipment.Xinrui has a total construction area of nearly 50000 square meters and over 500 employees. After more than ten years of industry experience and technology accumulation, Xinrui Company has developed into a one-stop medical parts and finished products full ecological chain service manufacturer integrating industrial design, mold design, mold manufacturing, injection molding, surface treatment, sheet metal processing, CNC processing, solid silica gel/liquid silica gel, finished product assembly, etc.

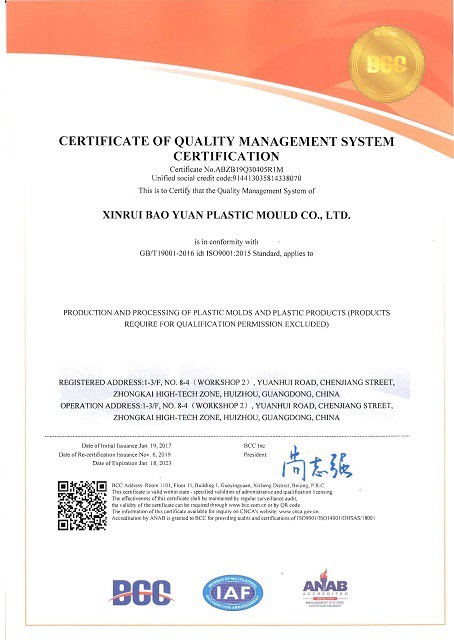

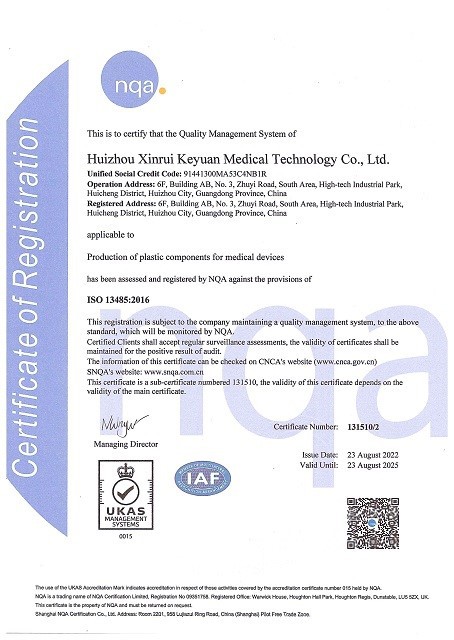

Certificate

FAQ

We're professional cnc manufacturers and suppliers in China, specialized in providing high quality customized service. We warmly welcome you to wholesale bulk high-grade cnc for sale here from our factory. For price consultation, contact us.

mould injection plastic, Transparent Injection Mold, cnc milling machining