Medical Cart

Why Choose Us

Rich Experience

After more than ten years of industry experience and technology accumulation, Xinrui Company has developed into a one-stop medical parts and finished products full ecological chain service manufacturer integrating industrial design, mold design, solid silica gel/liquid silica gel, finished product assembly, etc.

Quality and Price

Our products are of high quality and competitive price.

Production Capacity

Advanced production equipment and rich operating experience.

Customized Service

We provide customized products that can meet the strict requirements of customers.

What is Medical Cart

A medical cart is a movable piece of equipment used in healthcare facilities to store, transport, and dispense medicines, medical supplies, and emergency equipment. Medical carts come in various sizes, shapes, and configurations depending on the specific needs of the healthcare facility.

Benefits of Medical Cart

Mobility

Mobile medical carts can move from one location to another. This ability makes it easy for healthcare providers to bring supplies and equipment to the point of care, improving efficiency and reducing the time and effort required to retrieve supplies from central storage areas.

Customization

Medical carts are customized to meet the specific needs of different healthcare providers and settings. For example, a medication cart may include built-in medication dispensing systems, while a wound care cart may include supplies such as dressings, bandages, and cleaning solutions.

Storage

Medical carts offer ample storage space for supplies and equipment, which helps to keep items organized and easily accessible. They may feature drawers, shelves, and compartments, allowing healthcare providers to store items of different shapes and sizes.

Ergonomics

Medical carts with ergonomics in mind, which means they are comfortable and easy to use for healthcare providers. Adjustable handles, easy-glide drawers, and other features make them easy to maneuver and operate.

Security

Medical carts with locking mechanisms help keep supplies and medications secure. This feature is essential for carts that contain controlled substances or other sensitive materials.

Power supply

There are medical carts with built-in power supplies, which allow healthcare providers to charge electronic devices such as laptops, tablets, and mobile phones.

Types of Medical Cart

Emergency Carts

Emergency crash carts provide organized, portable storage with secure, easy access to critical-care supplies in emergency situations. The configuration of Emergency crash carts may vary, but most will be a waist high or chest-high wheeled carts with many drawers. Many hospitals will keep a defibrillator and heart monitor on top of the crash cart since these devices are also needed in most codes.

Anesthesia Carts

Anesthesia Carts are designed with a synergy of function and technology to meet the requirements for anesthesia storage, organization and security. Anesthesia carts are essential equipment for operating rooms within a hospital. Anesthesia carts provide storage for critical supplies and equipment required for patient procedures and surgeries.

Isolation Carts

Isolation carts are used to transport and store supplies and equipment used for patients who are in isolation due to infectious diseases. They are designed to prevent the spread of infection by providing a barrier between the patient and the surrounding environment.

Medication Carts

Medication carts are used to store and transport medications in healthcare settings. They are designed with drawers and compartments to organize and secure medications, and they often have locking mechanisms to ensure the security and safety of the medications.

Medical Computer Carts

Medical Computer Carts are designed for clinical settings. They eliminate back-breaking repetition when transporting equipment in examination rooms.

Medical Supply Carts

Medical supply carts are used to transport and store general medical supplies and equipment throughout healthcare facilities. They may include items such as gloves, gowns, cleaning supplies, and other general medical equipment needed in patient care areas.

Application of Medical Cart

Medication administration

Medication carts specifically for medication administration, typically featuring built-in medication dispensing systems, drawers for storing medicine, and secure locking mechanisms to ensure the security of controlled substances.

Emergency response

Emergency carts, also known as crash carts, are accessible during emergencies. They typically contain a range of emergency supplies, including defibrillators, airway management tools, and medications.

Procedure support

Procedure carts support medical procedures like wound care, dressing changes, and catheterization. They typically contain supplies such as gloves, gauze, cleaning solutions, and tools such as forceps and scissors.

Point-of-care testing

Point-of-care testing carts support diagnostic testing. They typically contain testing equipment and supplies, such as blood glucose monitors, rapid diagnostic tests, and collection devices.

Transport

Carts can move patients, supplies, and equipment throughout healthcare facilities. They can feature built-in oxygen tanks, patient monitors, and other equipment necessary for safe patient transport.

Storage

Medical carts can be used for general storage, providing healthcare providers with a convenient mobile storage solution for supplies and equipment.

Construction materials

Medical carts are typically made from durable materials like stainless steel, aluminum, or plastic. The construction materials used depend on the specific needs of the healthcare setting, as well as the type of medical cart.

Size and weight

Medical carts come in a range of sizes and weights to meet the needs of different healthcare settings. They can range from small, lightweight carts used for transporting medications to larger, heavier carts used for emergency response or surgical procedures.

Mobility

Mobility is a critical feature of medical carts, as they must be easily moved throughout healthcare settings. Medical carts can be designed with different types of wheels or casters to provide ease of movement, and they may also include handles or push bars to assist with maneuvering.

Locking mechanisms

Medical carts may include locking mechanisms to keep supplies and equipment secure. Locking mechanisms may include a plastic seal lock mechanism, key locks, or digital locks that require a password or badge swipe to open.

Mild Steel

Powder-coated mild steel can be a great choice for the base material of your medical cart. Mild steel is generally less expensive than stainless or aluminum, and adding the powder-coated finish gives the product a durable, long-lasting, and beautiful finish. Aluminum can also be powder-coated and while it's more expensive than mild steel, it's a better choice when a key design factor is keeping the weight of the cart low.

Plastic Shrouding

Many carts are also entirely shrouded in plastic. Using thermoformed or injection-molded plastic covers or panels for your cart is a great way to achieve the sexy, rounded, curvy, organic shapes often seen on medical carts. The tooling cost for these types of parts can be expensive, so the projected sales volume of your cart should be reviewed to ensure plastic parts are justified.Underneath that plastic shell, you're likely to find a metal frame. This frame can be zinc-plated, e-coated or powder-coated in an inexpensive color, as it's never really seen by end users.

How to Choose Medical Cart

Security

Security is non-negotiable when handling medications. Medication carts need to have lockable doors, drawers, and containers. Most modern carts offer digital locks, keypads, or biometric scanners. Digital accessibility options have one distinct advantage – they allow you to track who accessed a cart and when. This keeps medication safe from unauthorized access. It also helps comply with safety protocols set by DEA and other federal or state regulatory agencies.

Capacity and Organization

Choose medication carts that meet your capacity and organizational needs. Look for carts with adjustable drawers and modular storage. You can customize these carts to fit your medication management needs. Effective organization improves workflow and reduces the risk of errors.

Mobility and Maneuverability

Med carts come with different wheels. Select carts with high-quality, smooth-rolling wheels suitable for your facility’s flooring. Your staff should be able to move the carts effortlessly from one end of the facility to another if needed. Also, the carts should seamlessly fit through rooms, hallways, doors, and lifts in your facility.

Durability and Maintenance

US hospitals spend around $16 billion each year on medical equipment maintenance and repair. This cost has been increasing yearly by an average of 3.5% in recent years. Invest in durable, high-quality medication carts to keep these costs under control. For example, look for carts with surfaces that are easy to clean and withstand daily use. These simple considerations can go a long way in reducing your overall maintenance costs.

Technology Integration

Your facility will already have electronic documentation, barcoding, and password-protected access, among other things. Choose med carts that you can easily integrate into your existing tech ecosystem. This can significantly boost patient safety, reduce errors, and make your staff more productive.

What to Expect at Each Stage of the Medical Cart Design Process

Concept Stage

The Concept Stage is where we take note of our customers’ ideas, the features needed, and functional requirements. Once all requirements have been collected, three to five industrial design concepts are created and presented to the customer so that they can choose their preferred design features, which allows us to create the ideal final concept. The general lead-time for this stage is a week. Check out HUI’s blog on the Unique Concept Stage Process for a more in depth understanding.

Engineering Stage

This stage brings the custom medical cart to life. In the Engineering Stage, 3D models are assembled and all assembly and building details are processed. During this stage, HUI has regular meetings with the customer to review the models and make sure everything is being done to the customer’s satisfaction. Sometimes we also build a functional prototype, which is used to test design theories. This can be an entire cart or a specific section of the cart and is done to.

Prototype Stage

We begin the Prototype Stage by making prints and assembly instructions for the manufacturing floor. When the prints are complete, we hold Process Failure Effect Mode Analysis (PFMEA) meetings where we determine any plausible risks associated with our custom medical cart processes. We then sign off on the prints, completing all PFMEA actions. This allows us to start building the production-grade prototype.

Production Stage

The final stage of our medical cart process is the Production Stage. After we have made any final changes to the production grade prototypes, the medical cart goes into production. Generally, we produce 5-25 units for every production run. This way, we can continue to make additional changes at the request of our customer, if necessary. We also offer the ability to drop-ship products.

How to Maintain Medical Cart

Regular inspections

Regular inspections of medical carts are critical to ensure that they remain in good working condition and are safe for patient care. Inspections should include checks of wheels, brakes, locks, drawers, and compartments to ensure that they are working correctly. Regular inspections can also identify any damage or wear and tear that may require repairs or replacement.

Cleaning procedures

Medical carts must be cleaned regularly to prevent the spread of infection and maintain a hygienic environment. Cleaning procedures should follow facility guidelines and may include using disinfectants and cleaning agents that are safe for medical equipment. Drawers and compartments should be emptied and cleaned regularly to prevent the buildup of dirt, dust, or other contaminants.

Repairs and replacement

Medical carts may require repairs or replacement over time due to wear and tear or damage. Repairs should be carried out promptly to prevent any risk of injury to patients or staff. Replacement may be necessary if the cart is no longer fit for purpose or if it is beyond repair. Replacement carts should meet the same standards as the original cart to ensure that patient care is not compromised.

Our Factory

Xinrui Company was established in 2005, focusing on the R&D, designing, processing and production of components for medical equipment.Xinrui has a total construction area of nearly 50000 square meters and over 500 employees. After more than ten years of industry experience and technology accumulation, Xinrui Company has developed into a one-stop medical parts and finished products full ecological chain service manufacturer integrating industrial design, mold design, mold manufacturing, injection molding, surface treatment, sheet metal processing, CNC processing, solid silica gel/liquid silica gel, finished product assembly, etc.

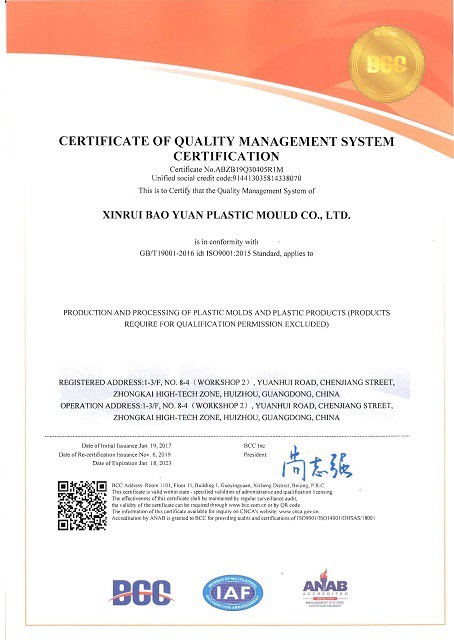

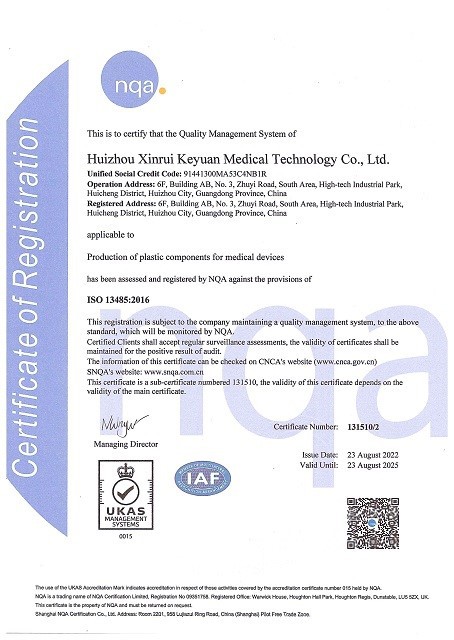

Certificate

FAQ

We're professional medical cart manufacturers and suppliers in China, specialized in providing high quality customized service. We warmly welcome you to wholesale bulk high-grade medical cart for sale here from our factory. For price consultation, contact us.

Mobile Medical Trolley, Medical Rolling Cart, Ultrasound Scanner Medical Trolley